Case Study: 20% Less Nitrogen, 8% Higher Yield, and 0.14 tonnes per hectares Lower CO₂ Emissions in Corn – Jataí, Goiás

Introduction

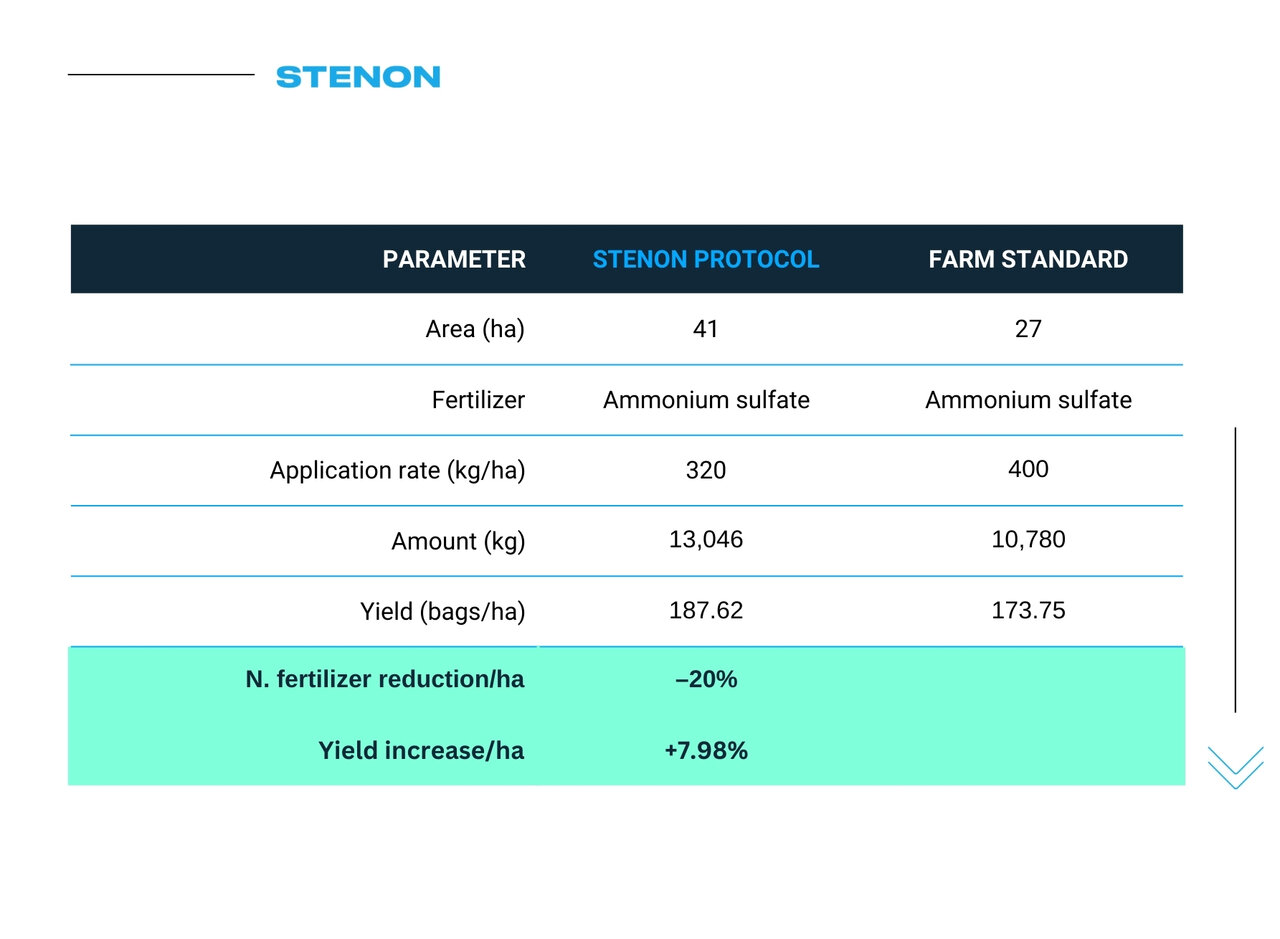

In Jataí, Goiás, corn producer Maristela Storti achieved impressive results by adopting Stenon’s real-time soil analysis technology. On the fields planted with the high-performing Pioneer 3898 hybrid, the farm recorded a 7.98% higher yield compared to its traditional approach, while reducing nitrogen input by 20% with the help of Stenon’s innovative solutions.

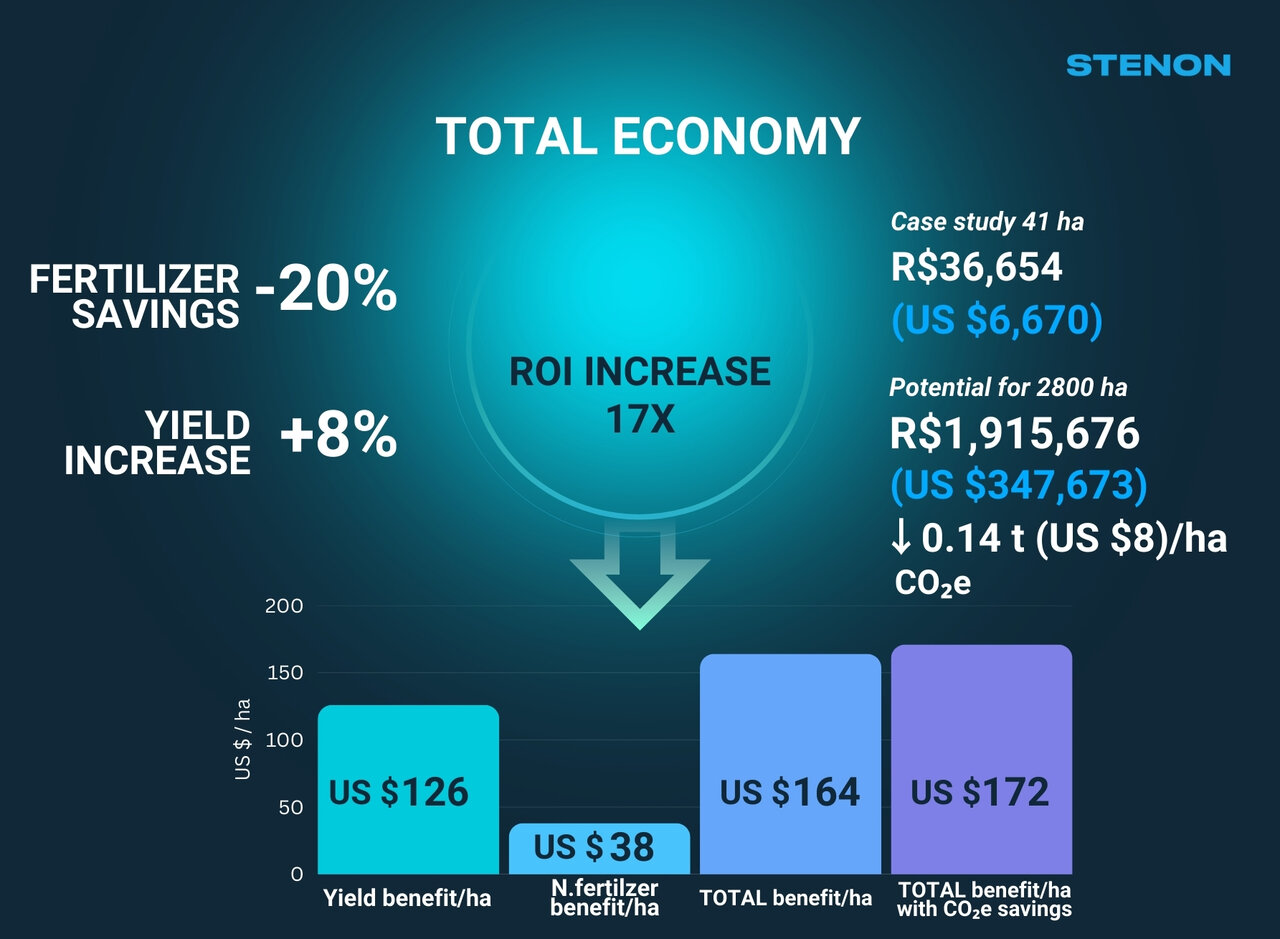

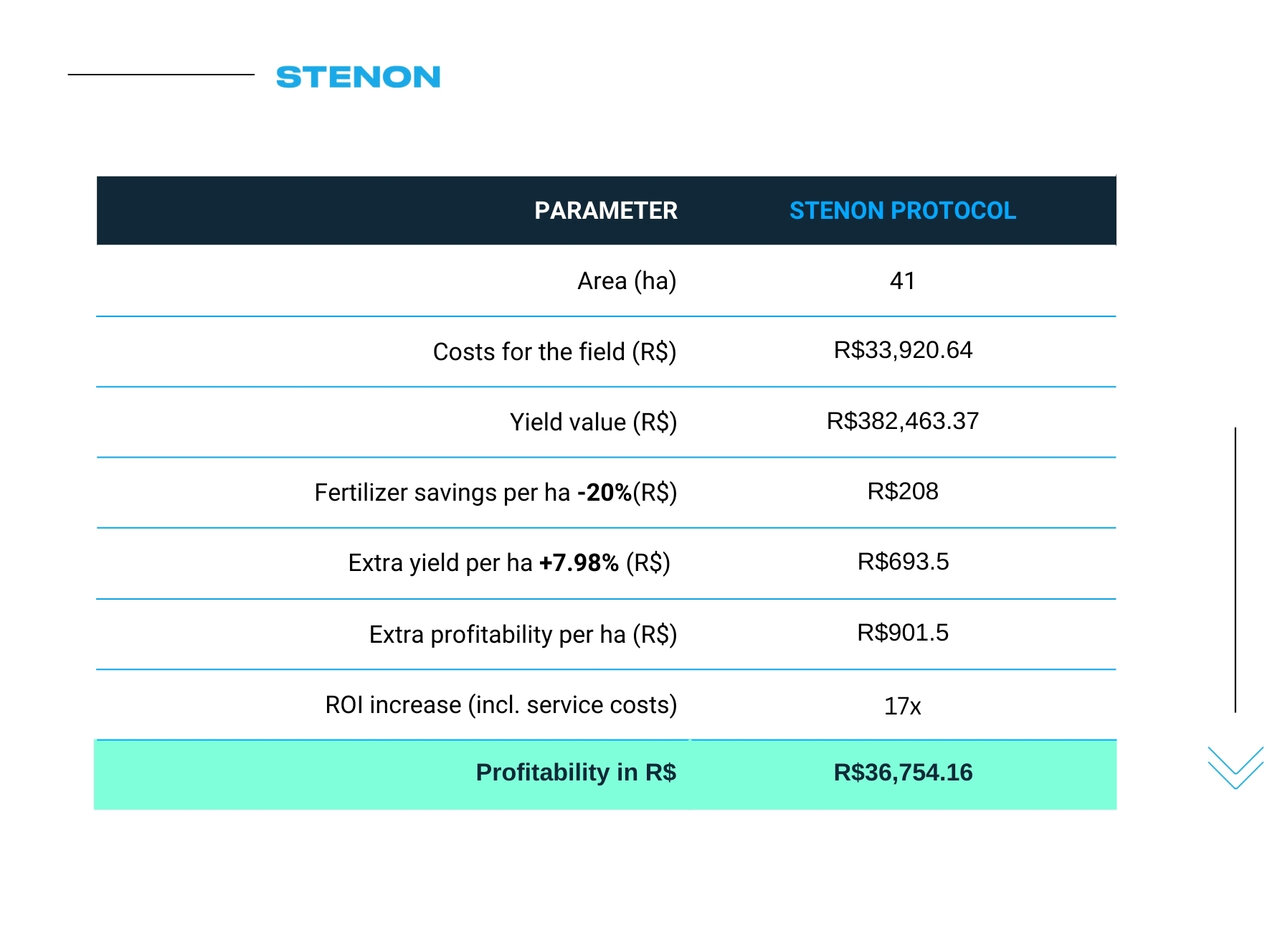

This optimized fertilization strategy led to a profit increase of US$163.61 (R$901.50) per hectare and a total ROI boost of 17x on the trial field. Scaled across the full production area, this would represent a potential profitability gain of over US$347,673 (R$1,915,676). At the same time, smarter nitrogen management can help reduce fertilizer-related emissions by an estimated 0.14 tonnes/ha of CO₂e, representing a climate value of nearly US$8 (R$45)/ha.

The case shows how targeted fertilization, supported by real-time soil data, can unlock significant agronomic, financial, and environmental value - all while maintaining productivity and improving long-term soil resilience.

This success story is part of Stenon’s broader effort to validate the benefits of precision fertilization across diverse crops and regions in Brazil. Through real-time measurements, crop-specific recommendations, and structured field evaluations, Stenon empowers farmers to make more informed decisions and achieve more using less.

Challenge

One of the key challenges in modern corn production is balancing productivity with responsible input use, particularly when it comes to nitrogen. Over-fertilization remains a widespread issue and can be highly detrimental to both crop performance and long-term soil health.

Like many Brazilian growers, Maristela Storti was looking to boost yield and manage input costs, but the conventional fertilization protocol tended to apply fixed, high doses of ammonium sulfate commonly seen as a “safety net” for yield. However, this method often oversupplies nitrogen in some areas while undersupplying it in others. In practice, this means high-fertility zones receive more than they need, while low-fertility zones don’t get enough leading to uneven plant development and reduced yield potential.

This is exactly the type of challenge that precision agriculture and variable rate application (VRA) are designed to solve — by applying only what’s needed, where it’s needed.

“Over-fertilization doesn’t guarantee better results. Applying the same rate everywhere can actually limit yield potential — oversupplying some areas while undersupplying others. This imbalance disturbs soil health, affects the plant’s nutrient uptake capacity, and ultimately reduces productivity,” explains Thiago Mendonça, Stenon’s Market Development Manager.

The impact isn’t just agronomic. Over-fertilization contributes significantly to CO₂ emissions through the production, transport, and application of synthetic fertilizers. Excess nitrogen not absorbed by plants can also leach into water sources or volatilize as nitrous oxide, a greenhouse gas nearly 300 times more potent than CO₂.

For sustainability-focused partners like Agrex, who introduced Stenon’s technology to Maristela Storti these risks are particularly relevant. Reducing unnecessary nitrogen not only helps improve profitability and soil resilience but also aligns with broader environmental goals — making real-time, data-driven fertilization a critical innovation in the agricultural value chain.

Solution

Since launching operations in Goiás, Stenon has partnered with Agrex, one of Brazil’s largest agribusiness companies and a key player in the grain production chain. As part of this collaboration, Stenon and Agrex identified Maristela Storti as an ideal candidate for a structured case study. The farm’s ambition to increase productivity, combined with its openness to technology, made it a strong fit for testing the real-world impact of data-driven fertilization.

To help farms adopt innovation with confidence, Stenon applies a structured and transparent approach: each case study is conducted on a preselected area, guided by a customized protocol aligned with the grower’s goals. From soil analysis to harvest, every step is monitored and documented to ensure the results reflect real agronomic and economic impact.

For Agrex, these case studies are a strategic tool supporting the introduction of new technologies like Stenon’s real-time soil analysis across their network of producers. With clear data, strong outcomes, and grower validation, Agrex is able to bring innovation to market in a way that’s practical, scalable, and rooted in results.

In this study, most of the field operations were carried out using John Deere machinery, including a JD 8400 R tractor for planting and harvesting support, a Hercules 6.0 fertilizer spreader for soil fertilization and correction, and a JD S670 combine harvester for harvesting — ensuring high-precision execution and reliable collection of yield data.

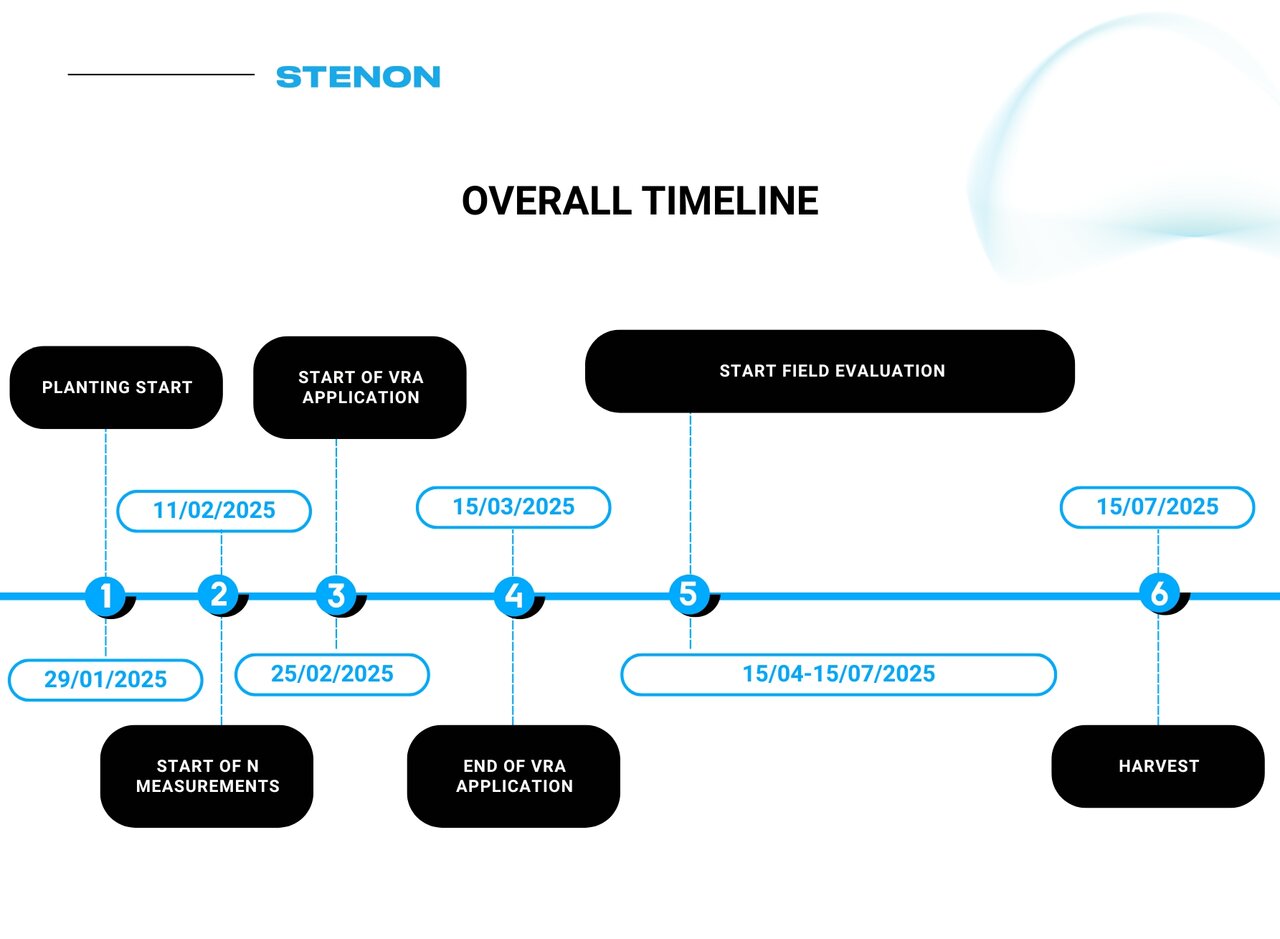

The field was planted on February 13th with the Pioneer 3898 hybrid. The plants developed uniformly and showed no water stress throughout the season — an excellent basis for analyzing the impact of fertilization strategies without weather-related bias.

This was a side-by-side field trial, allowing for a direct performance comparison between the farmer’s traditional fertilization and Stenon’s data-driven recommendation. The experiment aimed to evaluate real differences in input efficiency, yield, and profitability.

On February 25th, the first nitrogen application took place using a 15-15-15 base fertilizer (400 kg/ha) applied across both fields. Shortly after planting, NDVI imagery of the area began to reveal interesting patterns including certain zones with slower plant development. One such spot corresponded to the area previously used for limestone storage, where residual compaction or pH imbalances may have influenced early growth.

In addition, real-time soil analysis using the Stenon FarmLab detected a yellow zone — an area with low nitrogen availability, which was later traced to soil compaction caused by a former road that once crossed this part of the field. This insight prompted the farmer to take corrective action by tilling the specific area, improving soil structure and nutrient availability ahead of further crop development.

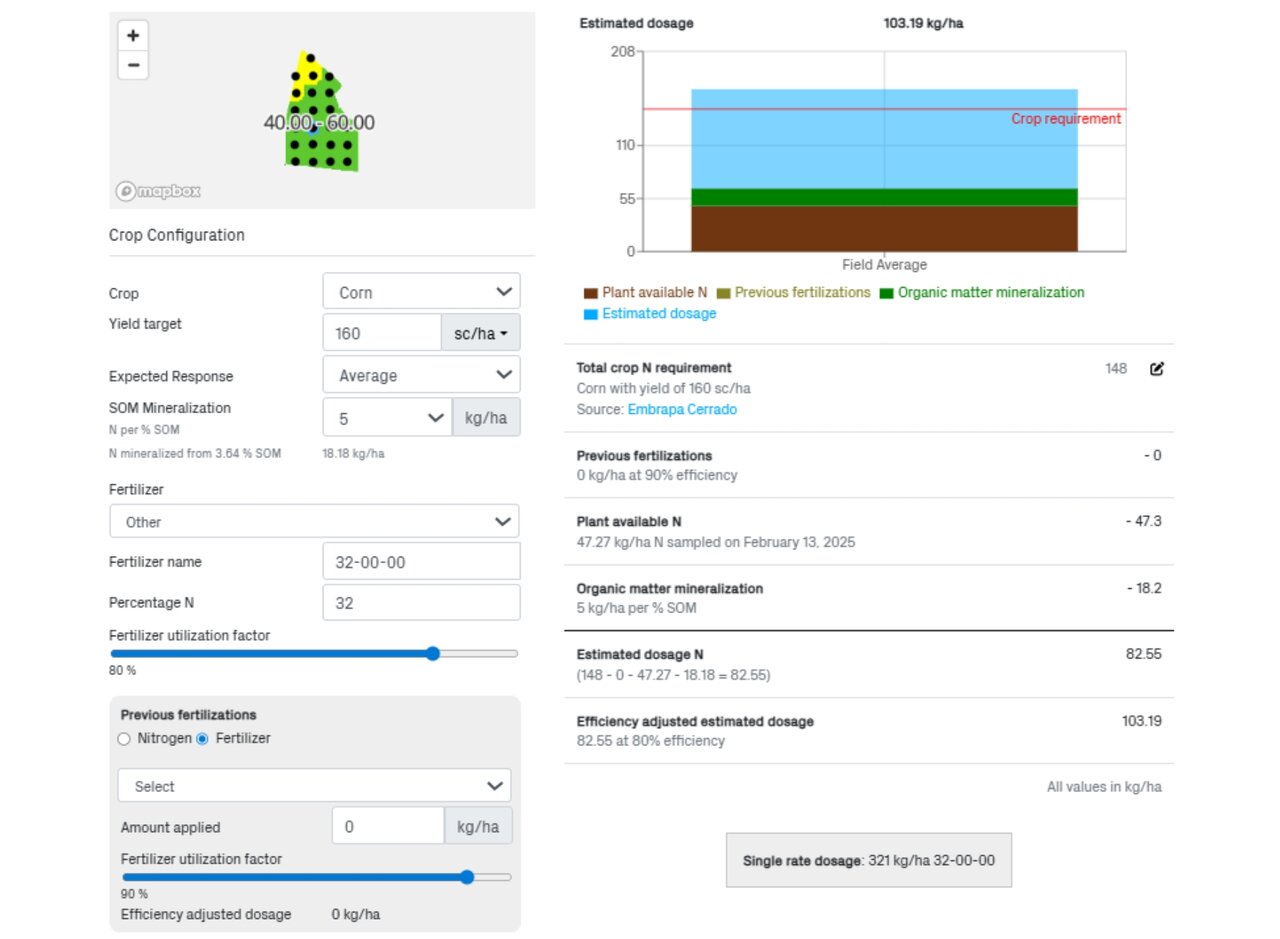

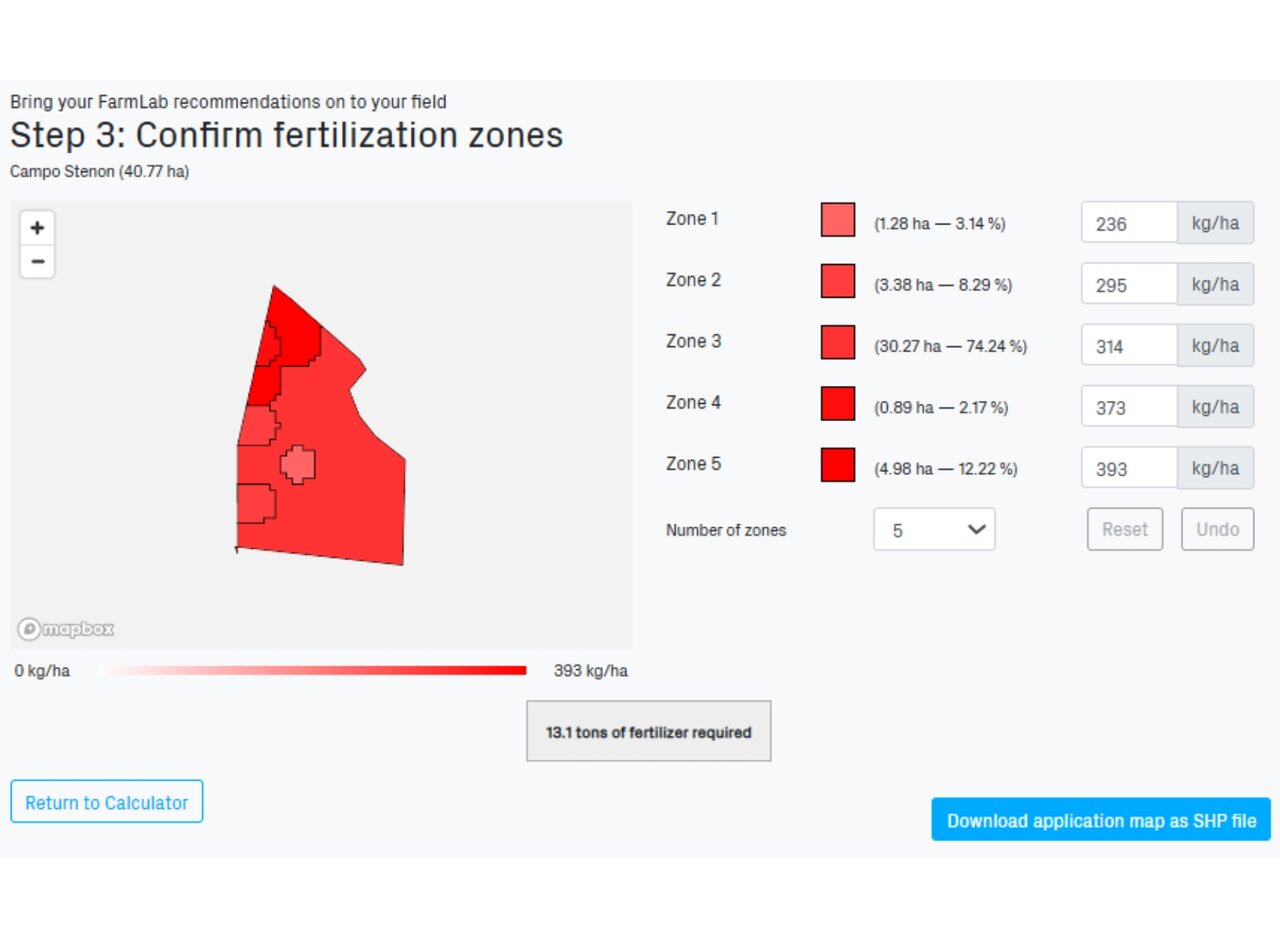

Based on the Stenon soil data, the second nitrogen application was adjusted: 320 kg/ha of ammonium sulfate was recommended, compared to the farmer’s standard 400 kg/ha — a 20% reduction. Despite the lower input, the Stenon-managed plot achieved a higher average yield per hectare, confirming the effectiveness of this tailored approach. These recommendations were generated directly in the Stenon WebApp, which visualized the nutrient distribution across the field and helped identify areas affected by historical variability. By factoring in both the target yield and real-time nutrient status, the platform delivered crop-specific fertilization plans that could be exported and used with VRA-compatible machinery such as John Deere, Stara, and Kuhn.

Stenon’s recommendation also aligned with a target yield of 160 sacks/ha, providing a practical balance between productivity and responsible input use.

The overall timeline for this case study was the following:

Results

The outcome was clear: better productivity with significantly less nitrogen. Despite applying 20% less nitrogen, the Stenon-managed field delivered 7.98% more yield per hectare than the farmer’s traditional approach.

I was truly impressed by the performance of the crop under this tailored fertilization strategy. With less nitrogen and better soil guidance, we achieved not only a higher yield but more confidence in the sustainability of our practices,

Economic Benefit

This case study clearly demonstrated the value of real-time, data-driven fertilization in delivering both agronomic and economic benefits, while also contributing to environmental goals.

By reducing nitrogen application by 20%, the farm achieved significant fertilizer savings without compromising performance. In fact, the Stenon-optimized plot not only maintained productivity, it outperformed expectations, with a 7.98% increase in yield compared to the farmer’s standard protocol.

This dual impact of lower input use and higher output resulted in a profitability gain of US$163.61 (R$901.50) per hectare, generating a total additional profit of US$6,670.45 (R$36,754.16) for the case study area. The return on investment (ROI) rose 17x, demonstrating the economic strength of precision fertilization when guided by accurate, real-time data.

Looking beyond the trial, the scalability of this approach is evident: applying the same strategy across Maristela Storti’s entire 2,800-hectare corn cultivation area would result in a projected profitability increase of over US$ 347,673.

In parallel, the reduction in nitrogen fertilizer use also translated into meaningful environmental benefits. The optimized fertilization approach prevented an estimated 0.14 tonnes/ha of CO₂e emissions, equivalent to the carbon footprint of dozens of long-haul flights or passenger vehicles. This emission reduction holds a market value of approximately $8 (R$45) per hectare, further enhancing the sustainability value of this practice.

Together, these outcomes highlight the power of real-time soil data to deliver a rare combination of higher yields, increased profit margins, and substantial environmental impact with proven potential for scaling across larger farm operations.

Conclusion

This case study from Jataí, Goiás, reinforces the tangible value of real-time soil analysis in modern crop production. By applying 20% less nitrogen and still achieving a 7.98% yield increase, Maristela Storti demonstrated that precision fertilization is not only effective, it’s transformative.

The approach resulted in a US$163.61 (R$901.50) profitability gain per hectare and a total ROI increase of 17x on the trial field, proving that smarter input use leads directly to stronger financial performance. On a larger scale, the projected benefit across the entire 2,800-hectare farm’ corn cultivation area exceeds US$347,673 (R$1,915,676.00), highlighting the scalability of this solution.

Beyond the economic advantage, the strategy also delivered measurable climate impact: 0.14 tonnes/ha of CO₂e emissions avoided, valued at nearly US$8 (R$45) per hectare in environmental savings.

This success confirms what data-driven agriculture can achieve: higher yields, lower costs, and reduced environmental footprint — all made possible by timely, accurate soil insights and technology that puts the power of precision directly into the farmer’s hands.