Matching Yield with 25% Less Urea fertilizer in corn production in Primavera do Leste, Brazil

Introduction

In Primavera do Leste, Brazil, Stenon’s real-time soil analysis helped optimize fertilization strategies for corn production on a trial field. Due to high rainfall and limited field accessibility, a single-application approach was essential. By leveraging Stenon’s precise soil measurements and variable rate application (VRA) technology, fully compatible with machinery platforms like John Deere, the farm achieved an impressive result: a 25% reduction in Urea use while maintaining high yields, outperforming the area’s historical average and matching the control plot.

This case is part of a broader series of studies Stenon is conducting across Brazil to demonstrate the effectiveness of its technology across different crops and regions. Working closely with major agricultural players such as machinery dealers and input retailers, Stenon provides more than just technology, our team of agronomic experts actively supports local farmers through on-site visits, ensuring the successful implementation and measurable impact of our real-time soil analysis solutions.

Importantly, this optimized fertilization strategy also contributes to reducing agriculture’s carbon footprint. If applied across the farm’s entire corn cultivation area, Stenon’s approach would result in an estimated reduction of 596 tonnes of CO₂ emissions. This includes savings from both lower nitrogen application and the emissions associated with fertilizer production and logistics – a critical factor for sustainability-driven partners.

The results achieved at São Jerônimo farm confirm once again: using real-time soil data is not only about reducing inputs; it’s about smarter, more sustainable farming that protects yield, improves profitability, and lowers environmental impact.

Challenge

Farm São Jerônimo manages over 3,800 hectares of soybeans and corn in Mato Grosso. In early 2025, they faced a familiar dilemma: how to meet ambitious yield targets (above the area's historical average of 140 bags/ha) under challenging field conditions.

Due to high silt content and heavy seasonal rainfall, splitting nitrogen applications wasn’t feasible, because the risk of machinery not accessing the fields was simply too high. Therefore, the client opted for a single urea application with more nitrogen input than historical practice, while trying out the advantages of precision agriculture and proper timing.

Solution

Fazenda São Jerônimo, owned by producer Victor Hugo and managed by Mr. Basílio, maintains a strong focus on increasing productivity year after year. Known for his openness to innovative solutions, Victor Hugo and Mr. Basílio had already discussed with Stenon ways to use real-time soil analysis to support this goal. Once the opportunity arose, Stenon’s team presented the concept, aligned on a detailed protocol, and began running trials, starting with soybeans and later with corn. This close collaboration, from application through to harvest, laid the foundation for the well‑structured and successful corn case study presented here.

In an industry where yield is paramount, growers often hesitate to adopt new technologies that might disrupt long-standing practices, even when those practices are less efficient. To address these concerns, Stenon case studies are conducted on preselected plots under a controlled methodology designed to deliver measurable, unbiased results. Each study includes five key steps:

Real-time soil analysis using Stenon’s technology

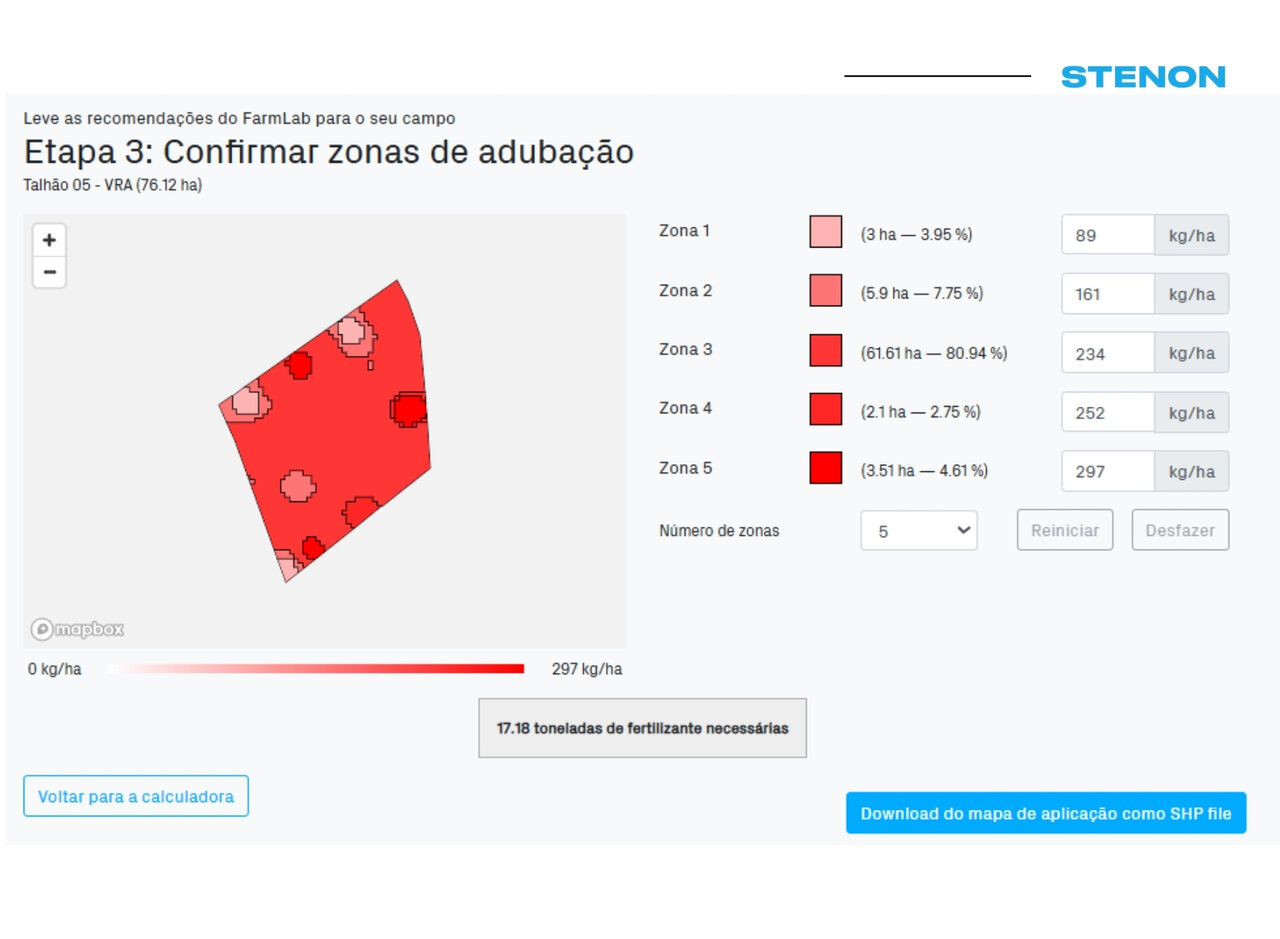

Instant fertilizer recommendations via the Stenon WebApp

Fertilizer application

Visual crop evaluation

Harvest performance analysis

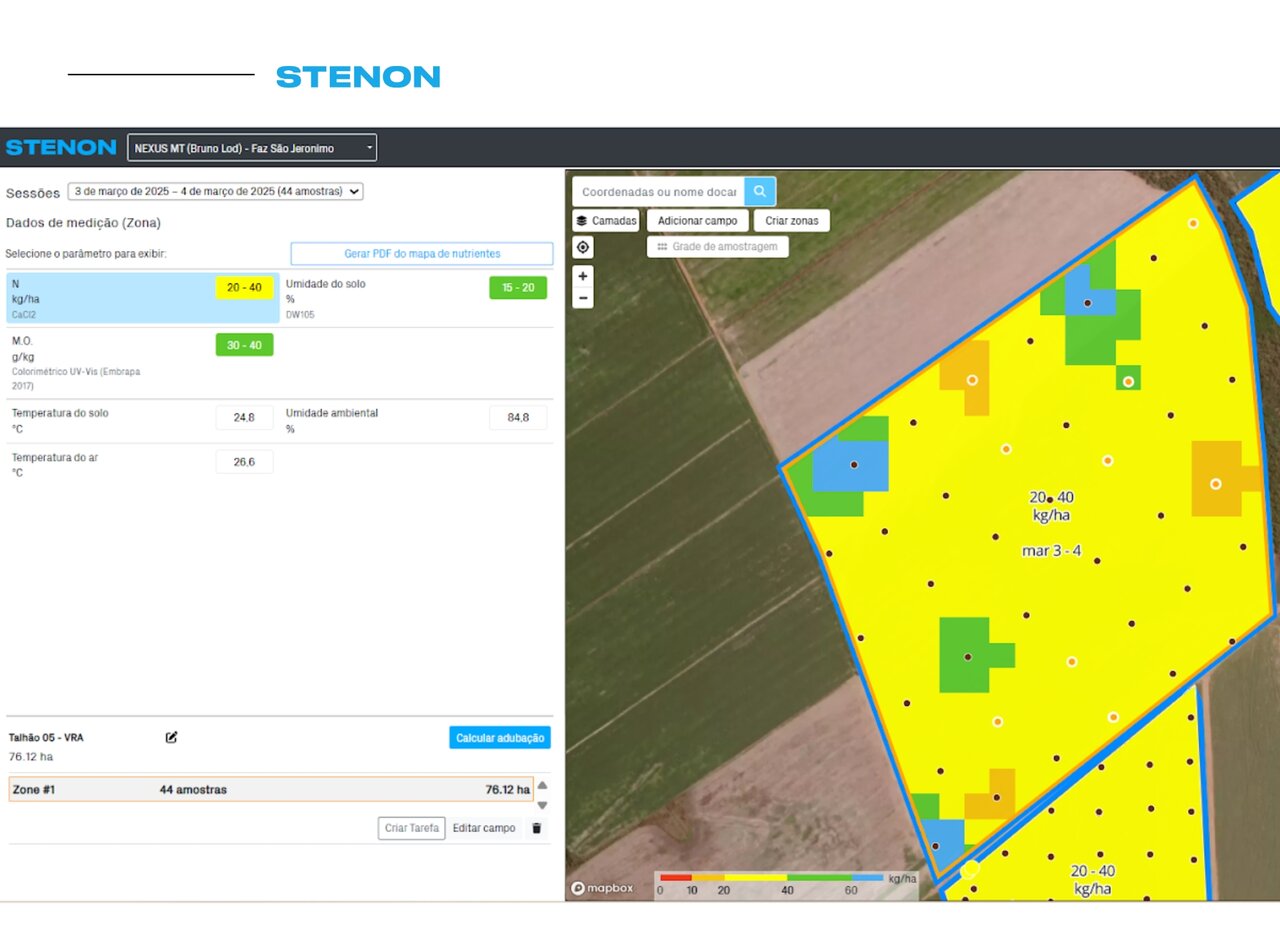

Each case study is designed around the grower's specific goals, providing clear insight into the impact of Stenon’s customized solutions. At Fazenda São Jerônimo, the objective was to optimize corn production on a 76-hectare field using real-time soil data, a single urea application, and variable rate application (VRA) technology.

The timeline for this case study was the following:

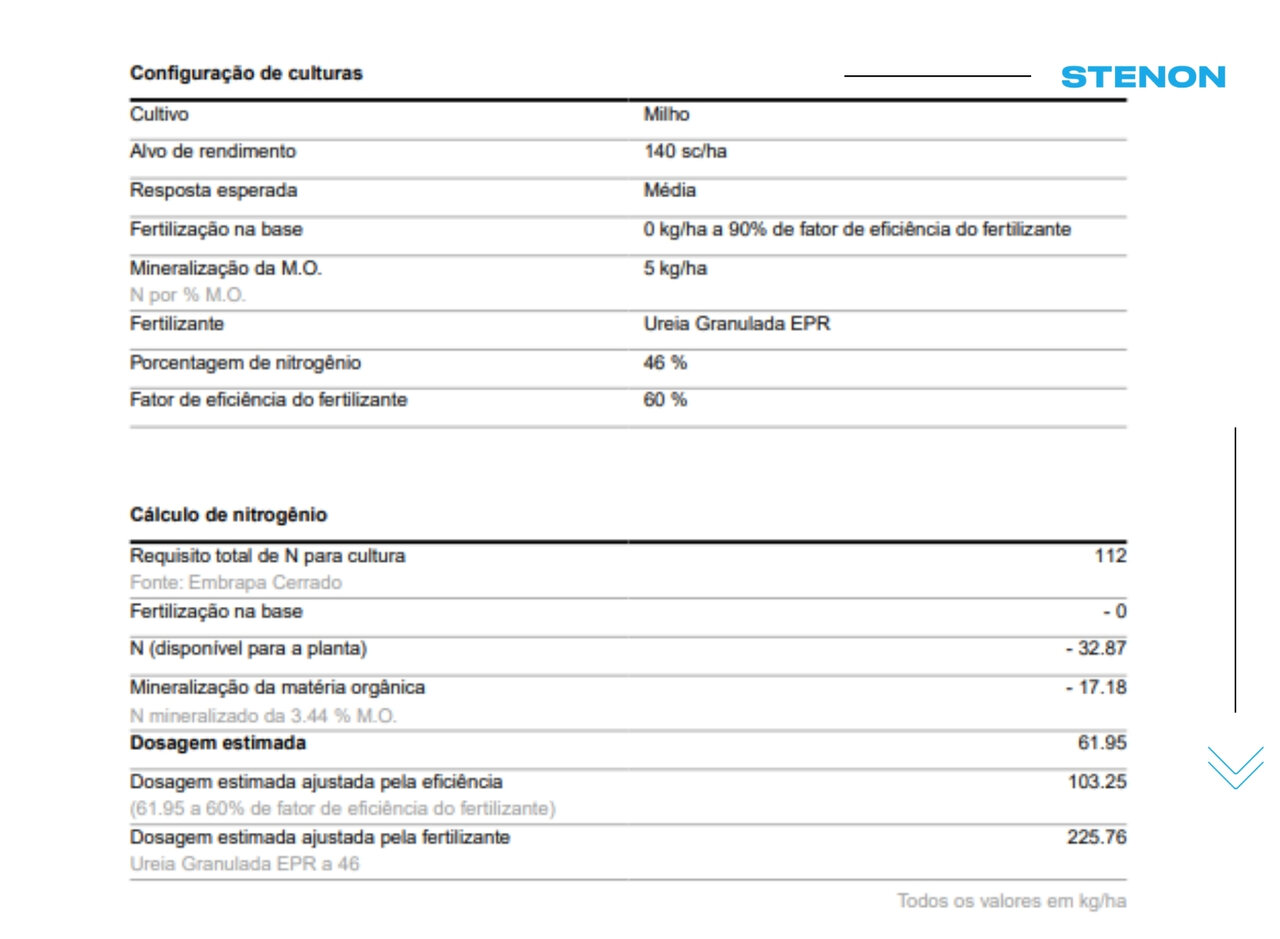

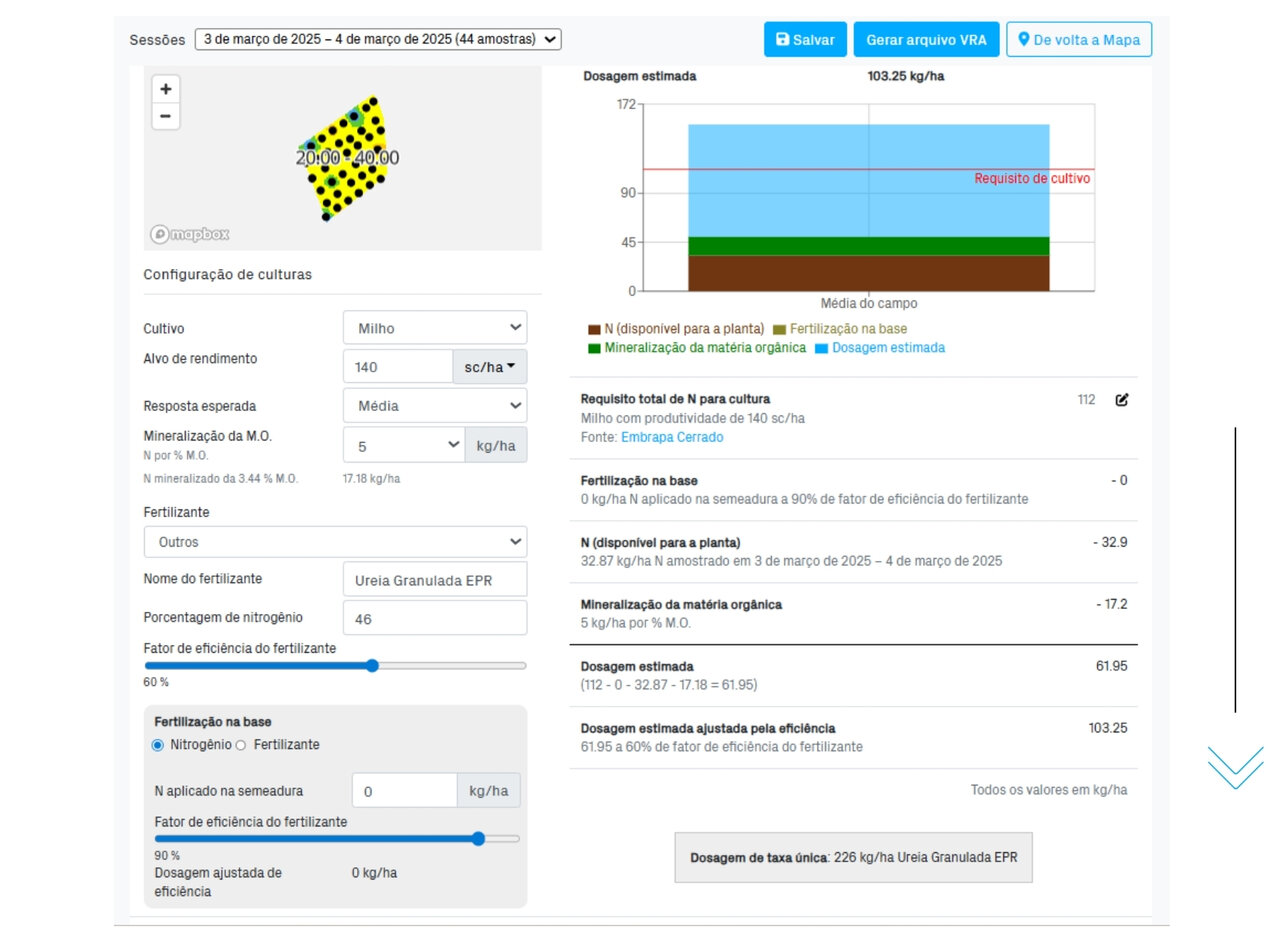

March 4, 2025: Soil measurements conducted using Stenon FarmLab

March 8, 2025: Fertilizer application carried out using VRA maps from the Stenon WebApp

Urea dosage: 226 kg/ha (Ureia 46%)

Yield target: 140 bags/ha

June 5, 2025: Pre-harvest crop evaluation performed by Stenon’s agronomic team

July 23, 2025: Final harvest conducted (161 bags/ha for both Stenon’s protocol and standard farm protocol)

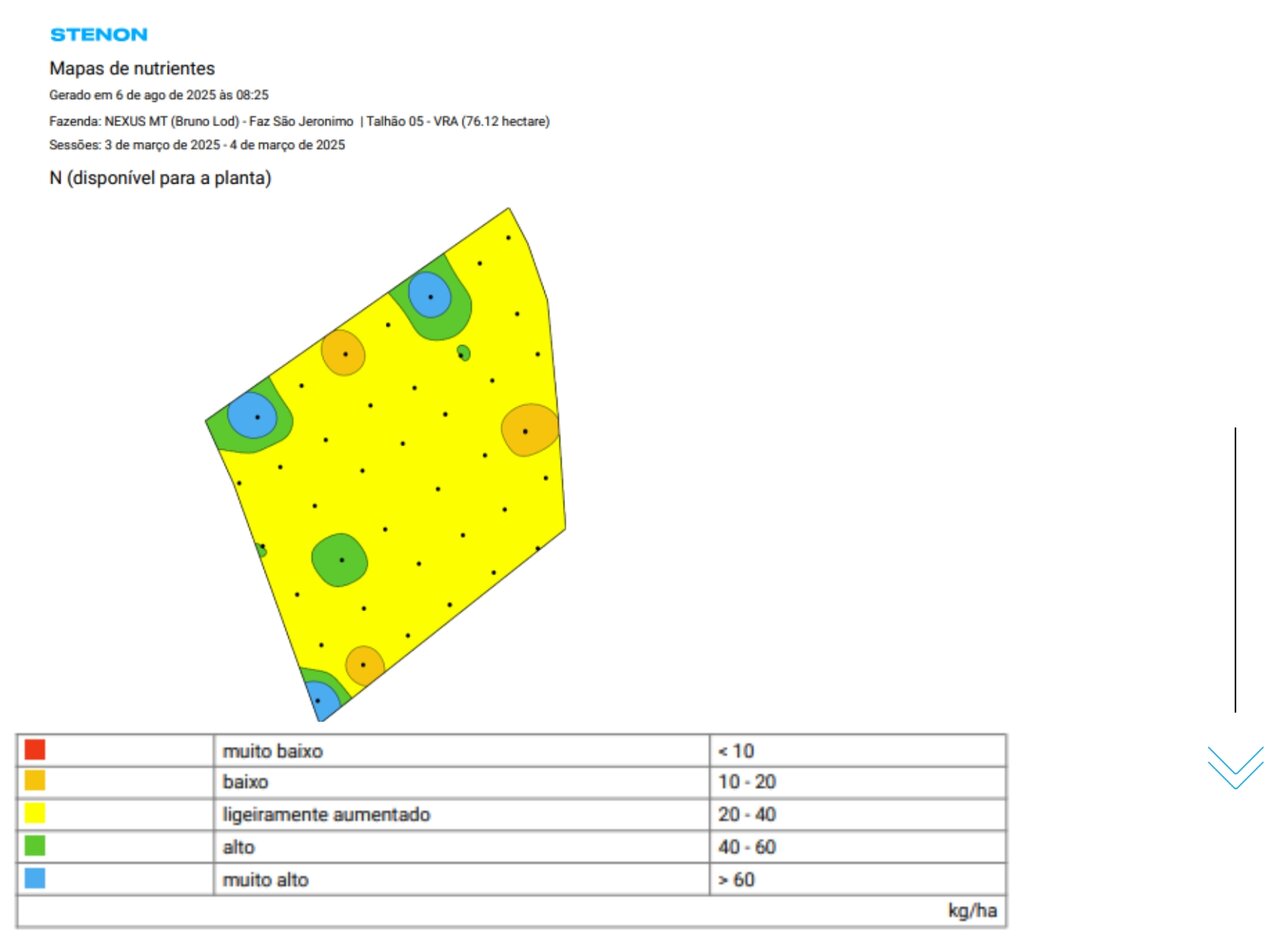

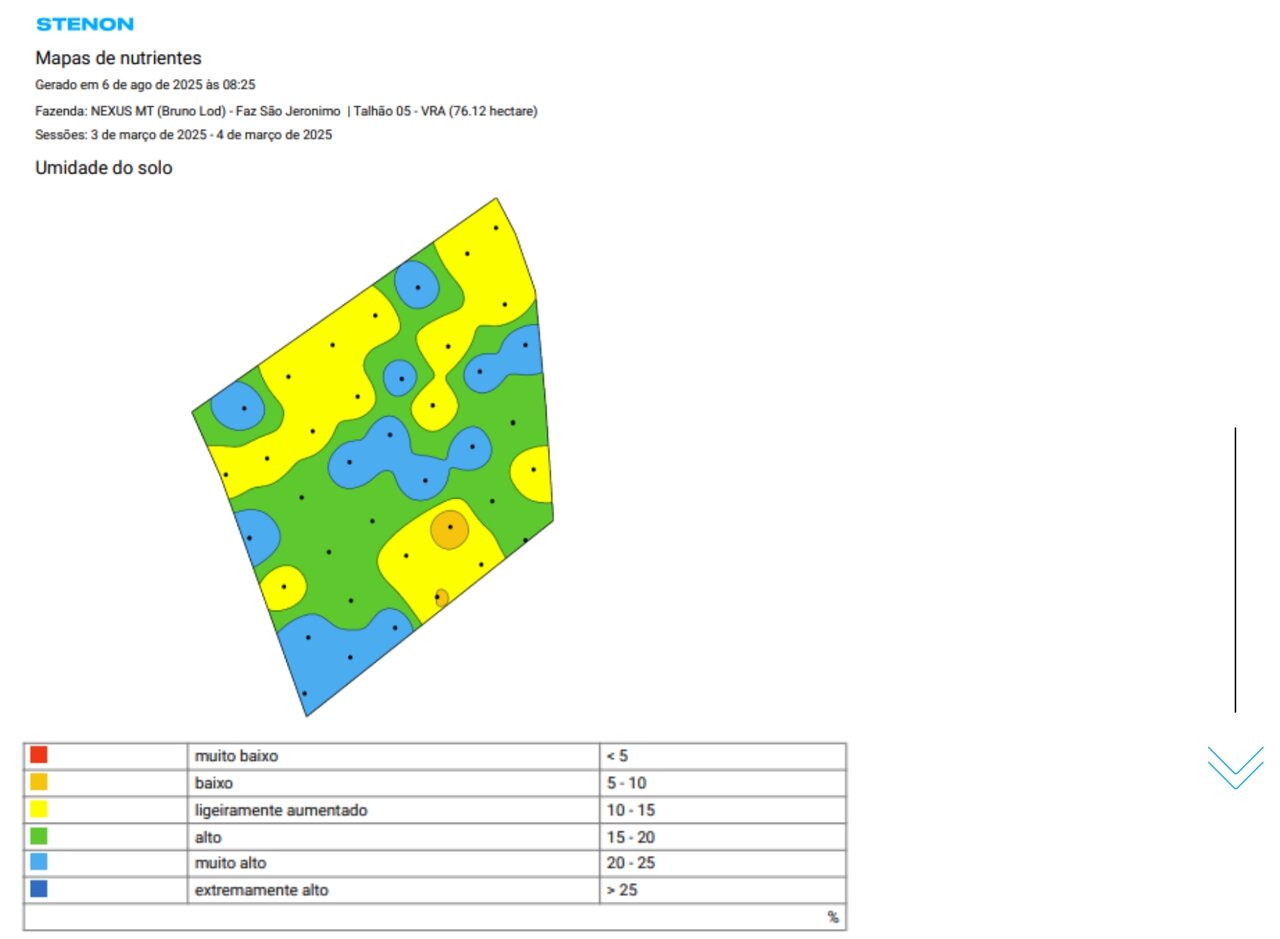

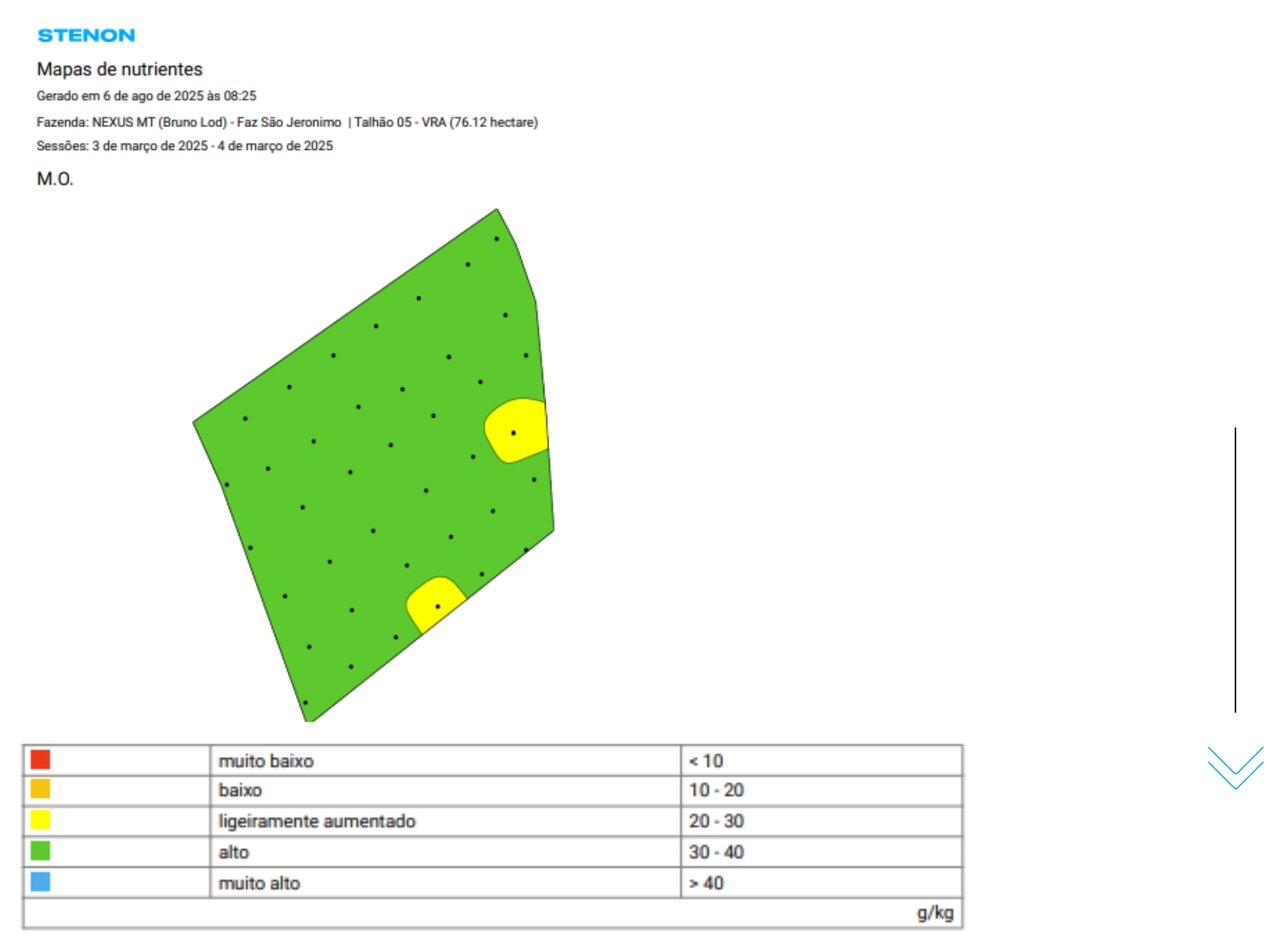

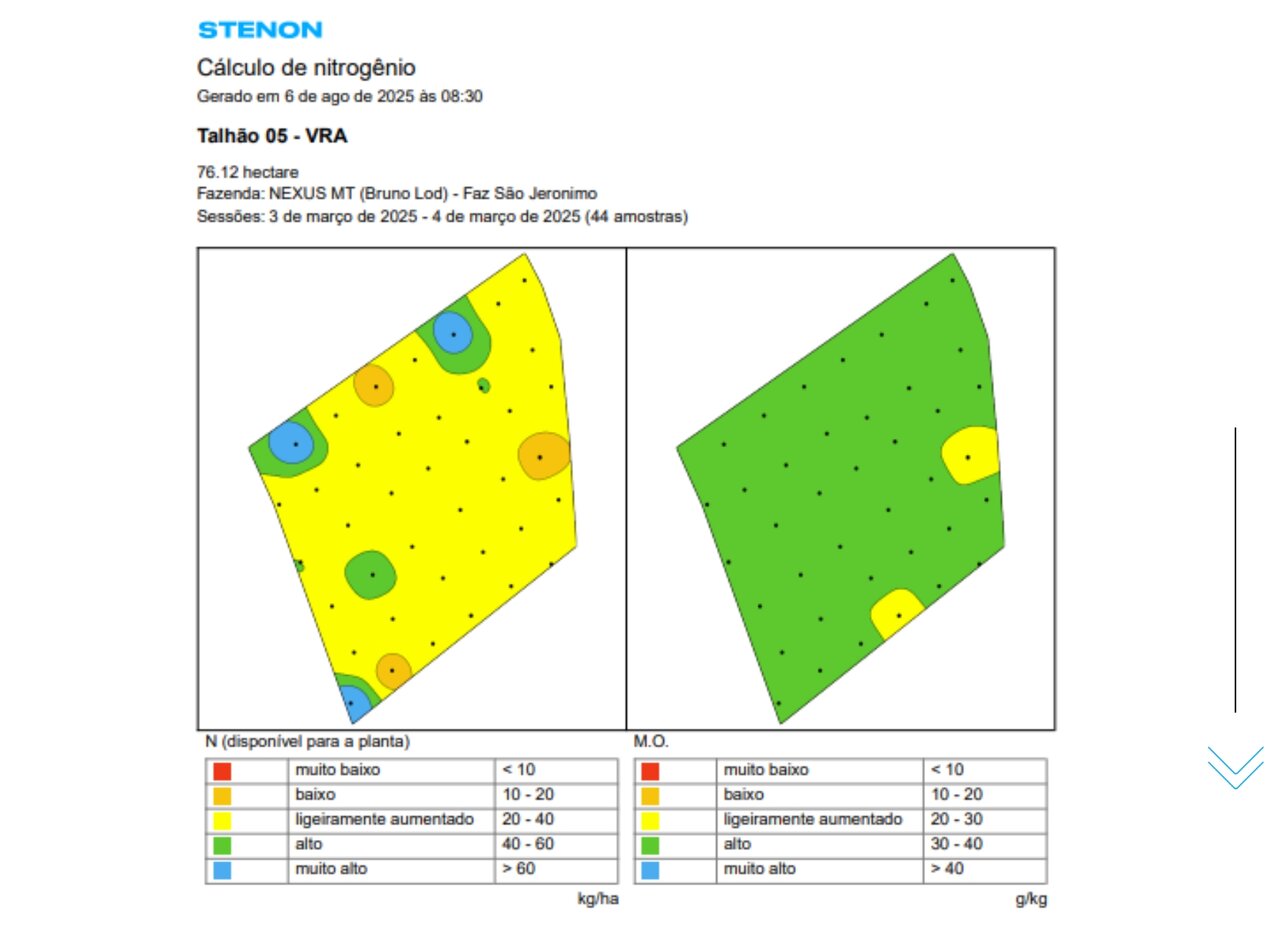

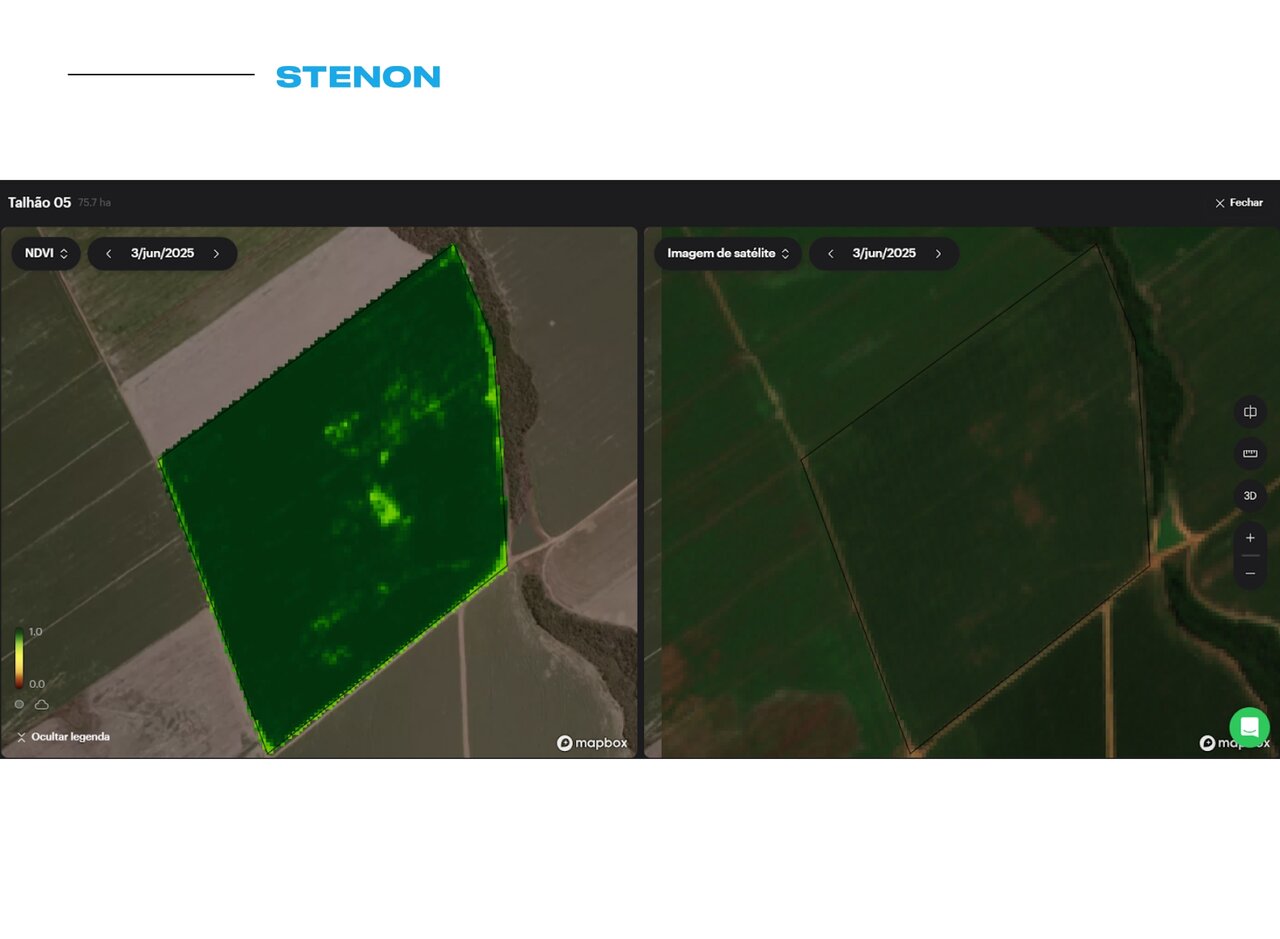

The results from FarmLab’s measurements were instantly available in Stenon’s WebApp, enabling the farm manager to view key parameters such as plant-available nitrogen, soil moisture, and soil organic matter (SOM).

The nutrient maps provided a clear visual representation of the field’s actual soil conditions, helping to explain some historical patterns in its performance. What proved especially valuable for the farm manager was the WebApp’s ability to instantly generate fertilizer application recommendations tailored to the specific crop, including the target yield and the current nutrient status of the soil. Within seconds, the application produces a detailed report that can be exported and seamlessly integrated into various application monitors, such as John Deere, Stara, Kuhn, and others for variable rate application (VRA).

The crop evaluation included NDVI monitoring through OneSoil imagery, two technical assessments during the reproductive stage, and a harvest follow‑up, comparing the Stenon protocol with the farm’s traditional approach.

“We didn't just deliver a recommendation, we followed through with full crop evaluation to make sure the client could trust both the process and the results,” explains João Carmo, Market Development Manager at Stenon.

Results

The results at Fazenda São Jerônimo clearly demonstrate the power of real-time soil data and data-driven decision-making in modern agriculture. By optimizing nitrogen use without compromising yield, the farm achieved a highly efficient outcome reducing input costs while maintaining high productivity. This success reinforces the value of Stenon’s approach and builds trust with both growers and partners.

We were impressed with the outcome. Reducing urea by nearly 25% and still reaching our target yield proves how precise and reliable the technology is. It's a big win for both our agronomic team and our bottom line,

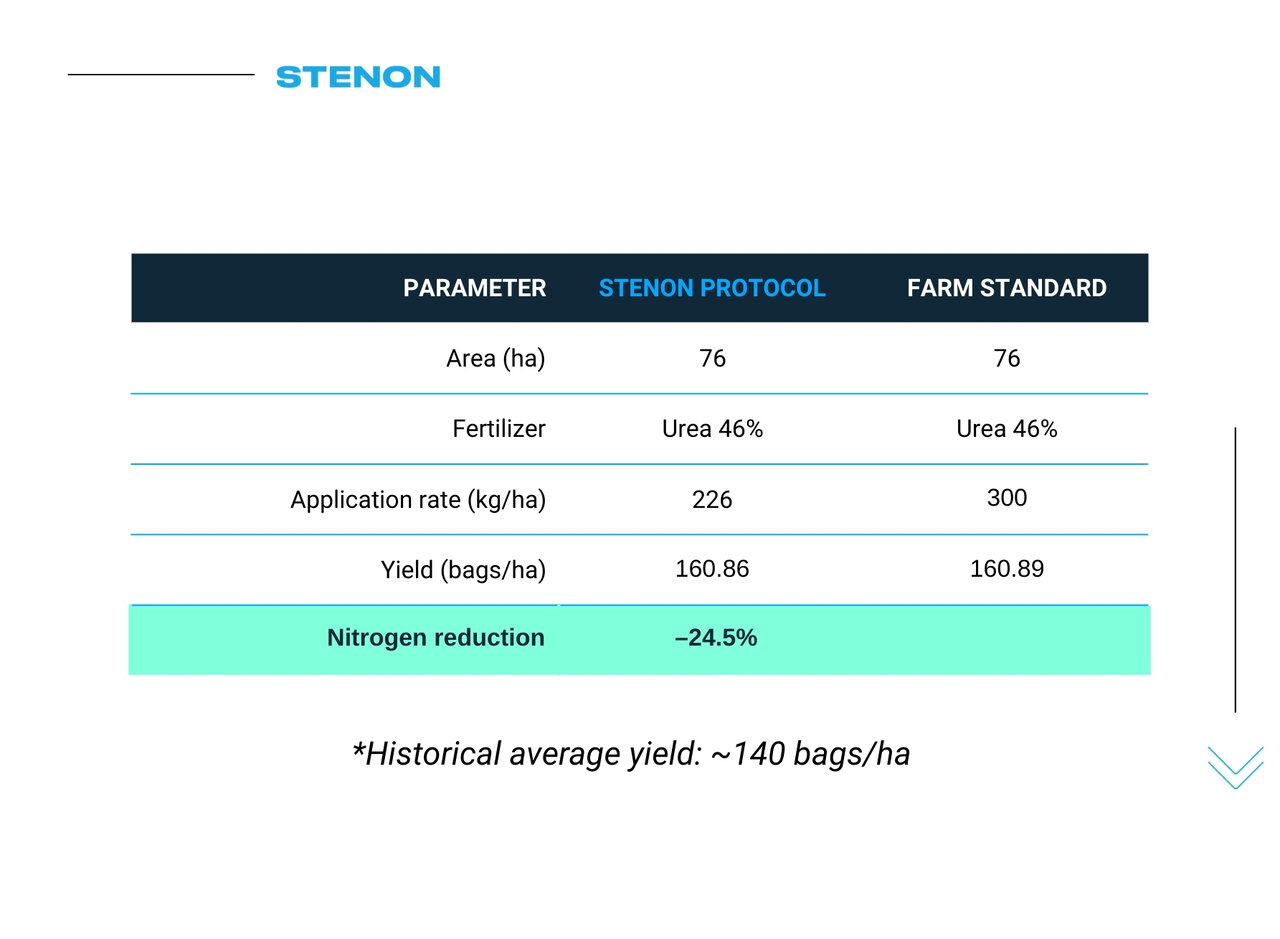

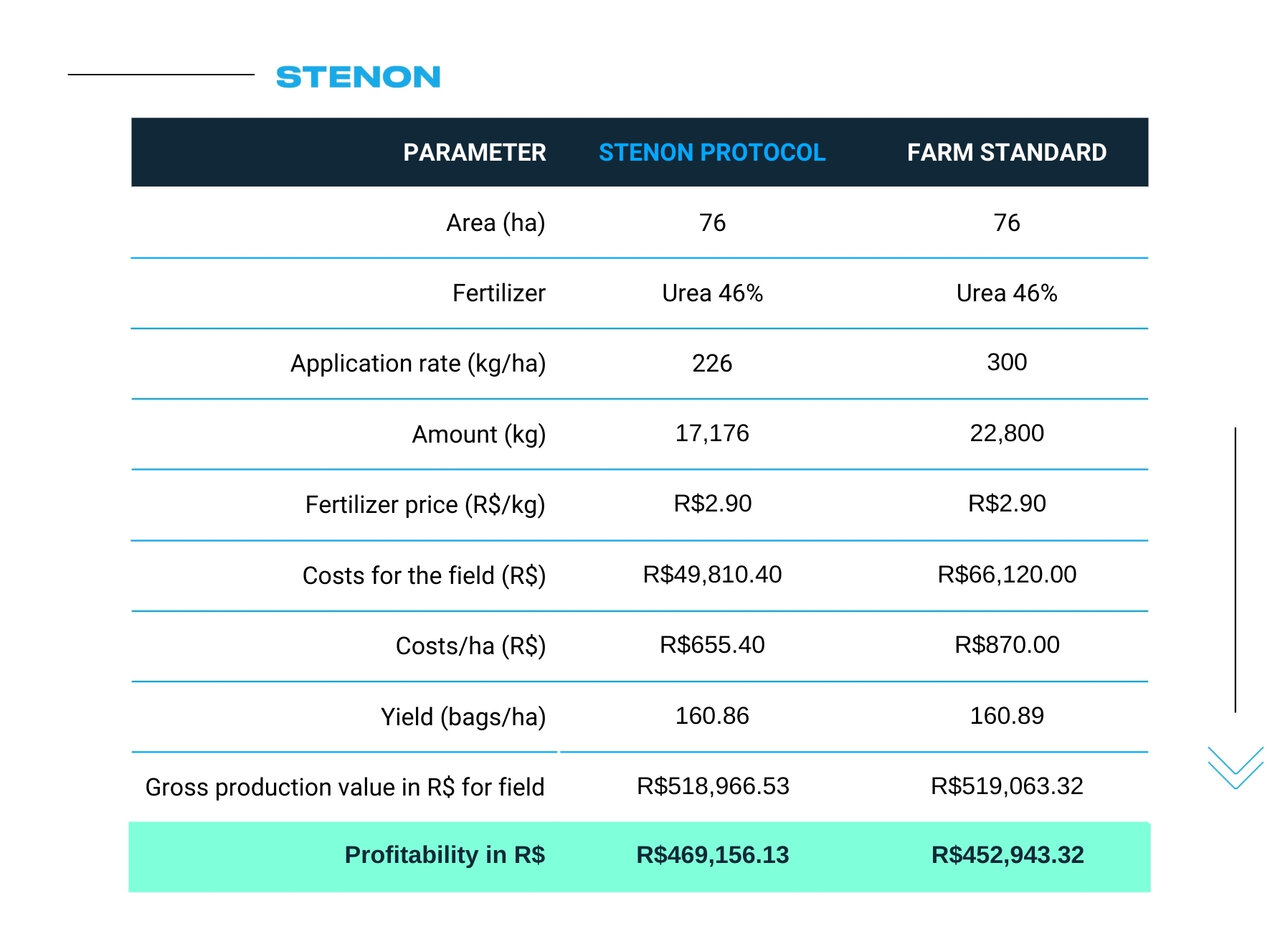

A side-by-side comparison of Stenon’s protocol and the farm’s standard approach revealed nearly identical yields, while input use was significantly optimized:

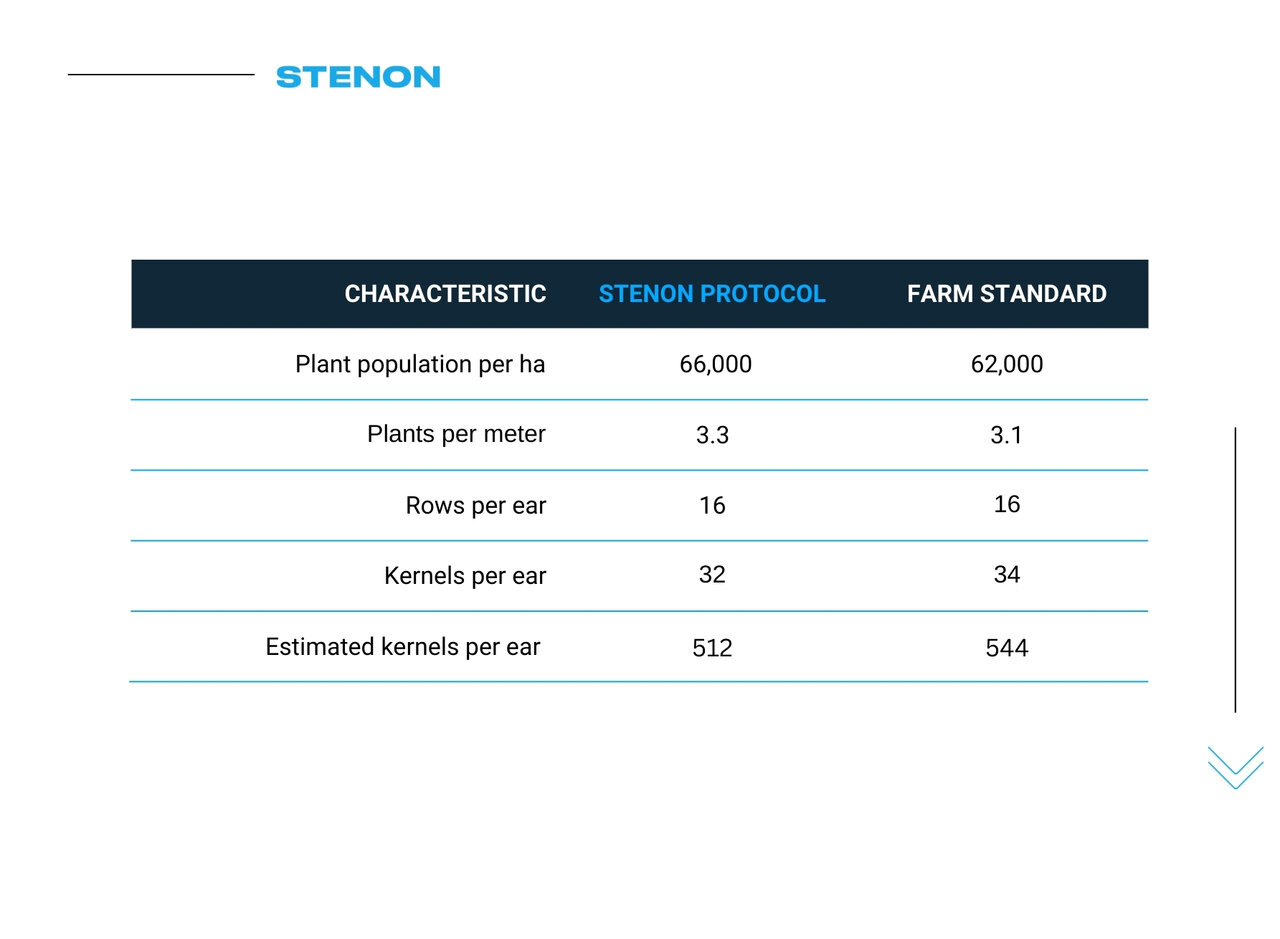

A technical visual evaluation was conducted during the reproductive stage of the corn crop by analyzing randomly selected plants within the field. The assessment focused on estimating yield potential and evaluating the agronomic performance of the hybrid variety.

The visual crop evaluation demonstrated the proven advantages of Stenon’s protocol.

The following images show a comparison of yield potential, where both treatments displayed similar characteristics in terms of the number of rows per ear, kernels per row, kernel weight, and overall grain quality. This highlights the balance between the two approaches, despite the reduced nitrogen input in the Stenon protocol.

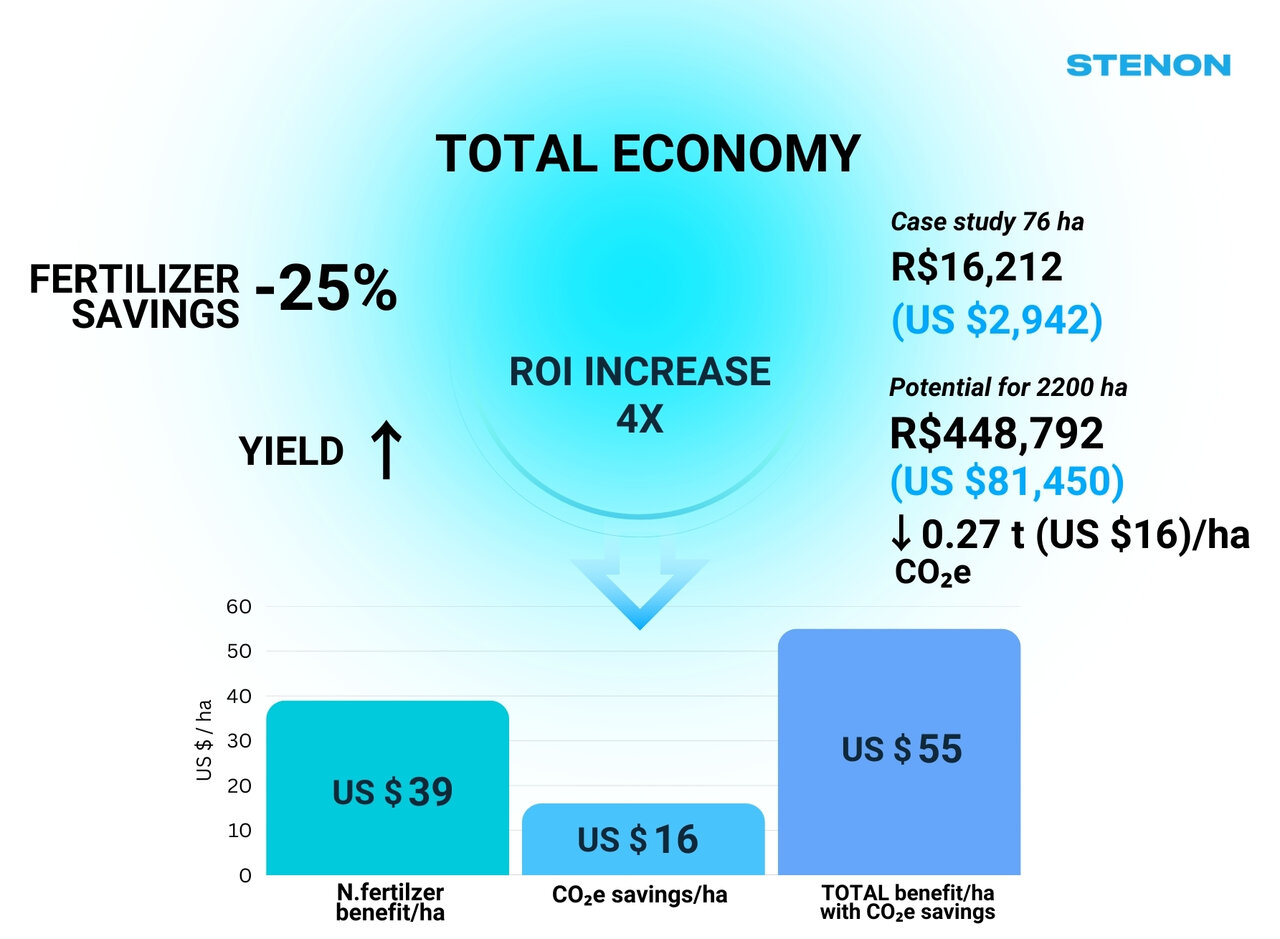

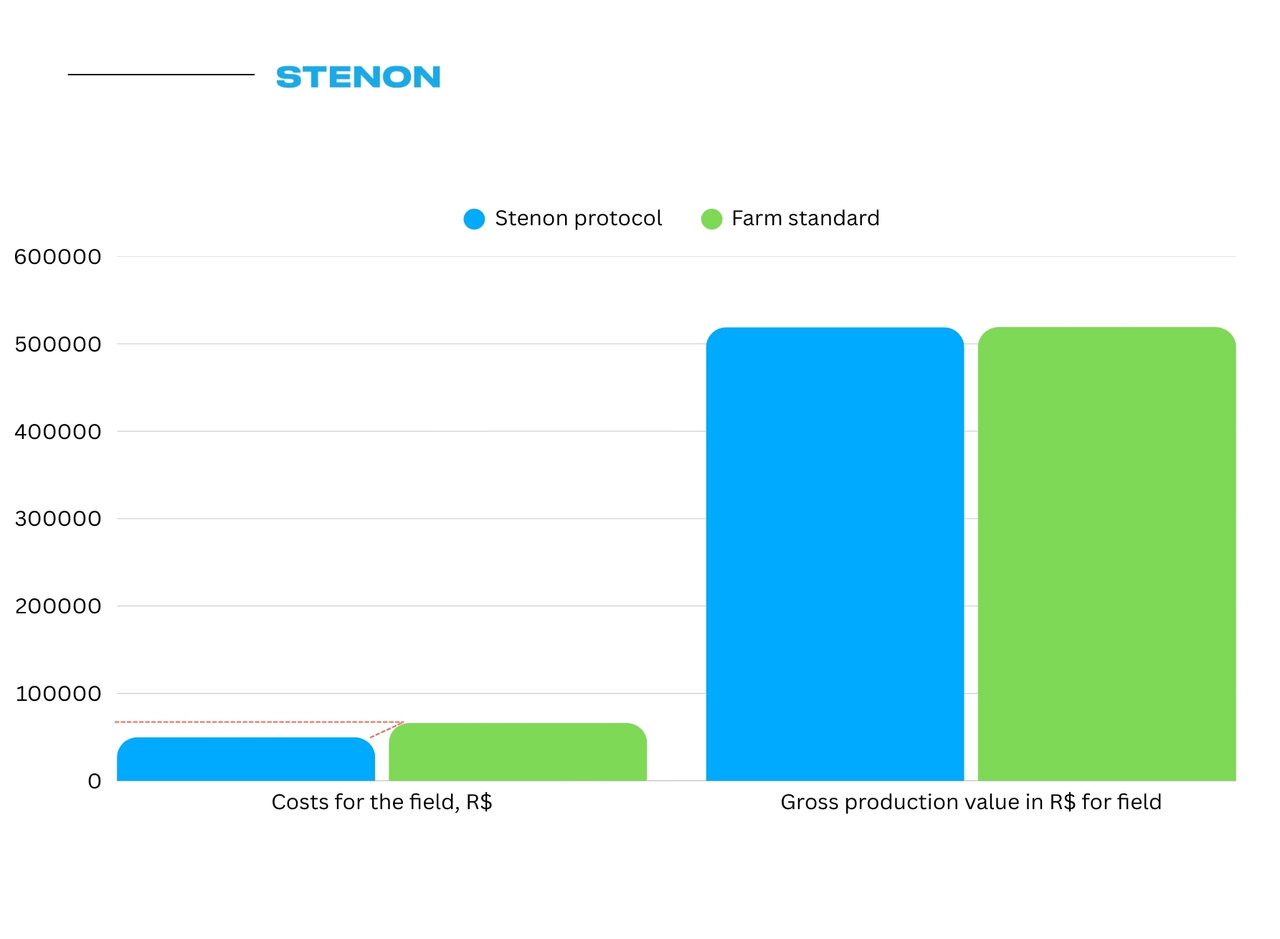

Another critical outcome to highlight is the economic benefit producers can achieve by applying Stenon’s real-time soil analysis and fertilizer recommendations. At Fazenda São Jerônimo, the use of 24.5% less urea on the 76-hectare trial plot translated into direct savings of R$16,212.81 ($2,942.43) with the came yield. If the same approach were extended to the farm’s entire corn cultivation area, the savings could reach R$448,792 ($81,450). Translating this impressive result into potential revenue for the farm, we are talking about the value equivalent to the additional yield of 5 bags/ha.

In addition to cost savings, the environmental benefits are substantial. By reducing nitrogen inputs, the farm also contributed to lowering its carbon footprint, avoiding up to 596 tonnes of CO₂ emissions — a key consideration for both forward-thinking growers and sustainability-focused partners.

Considering today’s input prices, market conditions, and the growing pressure for climate-smart agriculture, these results underscore the economic, agronomic, and ecological advantages of adopting real-time, data-driven fertilization practices.

Conclusion

The case study at Fazenda São Jerônimo clearly illustrates the agronomic and economic value of Stenon’s real-time soil analysis technology. By implementing a single, variable-rate application of urea guided by Stenon’s in-field measurements and digital recommendations the farm reduced nitrogen input by 25% without compromising yield. In fact, the yield matched the standard protocol and exceeded the region’s historical average by over 14%.

Beyond agronomic success, the economic implications are equally compelling. The input savings achieved on the trial plot alone demonstrate the strong return on investment possible when precision fertilization strategies are applied. When extrapolated across the farm’s full corn production area, the potential for substantial cost savings and increased revenue becomes even more significant.

In a competitive agricultural environment where every input counts, the São Jerônimo case proves that precision pays and that smarter decisions start with better data.